Giant duct bank to provide consistent flow of electricity

Construction is underway on a 110,000 linear feet electrical duct bank that will provide a consistent flow of power to Phase 2 of the Silver Line. This will connect the Dulles Corridor from the Wiehle-Reston East Station to Dulles Airport and west to Ashburn, linking the region to downtown D.C and beyond.

“The duct bank is a vital component to the overall operation and function of the rail system. The 34.5kV duct bank system provides the pathway for power to be distributed throughout the project,” said construction project manager Adam Rosmarin, of Capital Rail Constructors.

Overseeing the duct bank’s construction including the train control rooms and traction power substations (TPSS) is construction manager, Nick Perrotta of Capital Rail Constructors.

“The 34.5kV power is high voltage and will be pulled down from three areas on the project; the south end of Route 28, Phase 1 stations and the Shell Station substation located at the west end of the project. These three points will provide the primary and secondary power used to power the job,” said Perrotta.

“In addition, there are 15 wayside facilities also referred to as traction power substations (TPSS), where the primary power will then be stepped down into secondary traction power that will actually move the train and power the stations’ facilities such as communication signals and lights,” said Perrotta.

Due to the amount of voltage and traction power needed to run the trains, the power system cannot be laid above ground, said Perrotta. Instead, the duct bank is currently being constructed underground in order to eliminate any potential safety hazards and safely store the “extension cord” needed to feed the trains and stations.

There are certain requirements that must be followed when building a duct bank.

“For starters, a duct bank must be dug a minimum of 30 inches below cover”, said Perrotta.

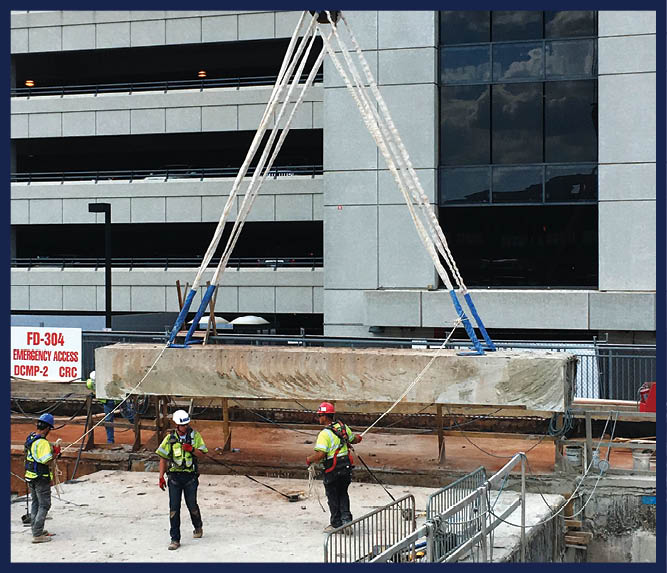

However, a large portion of the geographical layout for the Phase 2 Silver Line project calls for even deeper duct banks. In order to install this work at the increased depth, the use of trench boxes is required. Trench boxes are designed to span the width of a trench during excavation and pipe lying of a duct bank, said Perrotta. Trench boxes can help prevent the walls of a duct bank from caving in while being constructed, he said. The depth of a duct bank can determine how many trench boxes should be used.

- TPSS 13 Station, located west of the Herndon Monroe Park & Ride. Safety gear and all, Construction Manager Nick Perrota from Capital Rail Constructors and Stacey DaBaldo, MWAA intern for the Dulles Corridor Metrorail Project, tour the TPSS 13 Station. Photo by Lisa Sheffer

- TPSS 13 Station located west of the Herndon Monroe Park & Ride. Excavation is happening! Construction work continues on the TPSS 13 Station for the Phase 2 Silver line extension. Photo by Lisa Sheffer

Excavation for the duct bank requires a customized plan that accounts for various depths and pathways in order to maneuver around each utility. Utilities found in the pathway may include a cable line, storm drain or sprinkler head. The depth or type of utility can determine which pathway or depth a duct bank needs to be. Exact locations must be tested prior to continuing with excavation of the duct bank.

While utilities are mapped prior to excavation and are no surprise to construction workers, it is still necessary to “handle with care” in case any alternative methods need to be used, project leaders said.

Utilities have not been the only concern, said Perrotta. Large portions of the duct bank excavation revealed diabase; a type of granite rock that is unlike the native red soil in this area and cannot be easily removed or redistributed elsewhere.

While there are multiple techniques to get rid of the diabase rock, constructions workers are using drills to honeycomb the rock, making it easier to break with the use of a hammer.

“The honeycomb technique looks exactly as it sounds”, said Perrotta. A construction worker will drill several connected holes in the shape of a honey comb. This method helps weaken the strength of the diabase so it can then be struck and shattered into removable pieces.

In some areas of 34.5kV utility crossings, construction workers said that the drill heads for the jack and bore operation became stuck in the diabase during their first attempts to drill, forcing construction workers to resort to hand mining and manually chip away piece by piece of the diabase.

While there was no obvious way to account for the extent of diabase prior to beginning duct bank work, Capital Rail Constructors’ workers successfully re-configured the original course of action.

John Kearney, project construction manager overseeing Phase 2, is passionate about the Silver Line extension.

“This project is a landmark. It is not every day that you can point to something and say I had a small part in building that,” said Kearney.

Construction is set to be complete in 2019 and the project will then be handed off to Washington Metropolitan Airport Transit Authority (WMATA) for testing. WMATA will set the opening date, likely in 2020.

- PVC pipes located at Innovation Station. Pictured above are PVC pipes, located more than 10 feet underground in a trench that houses only some of the electrical supply needed to power rail cars at Herndon Station. Stacey DaBaldo

- Dulles Airport Station site. Construction of the Dulles Airport Station continues as a DCMP crew start to reconfigure the exterior of the pedestrian tunnel that will provide access for Silver Line passengers to the main terminal.